The year is 2012. Apple just released their latest and greatest technological feat – the iPhone 5. And the guy behind the counter at your local supply shop is explaining how these new fittings for connecting carbon steel and black iron pipe don’t need to be grooved, threaded, or welded. You just put a hydraulic press tool on the fitting, press the trigger and a permanent mechanical connection is made in seconds.

We get how that may have sounded too good to be true at the time. But after 10 years, hundreds of configurations, thousands of approvals, more than 2,500 standard and nonstandard applications* and more than 22 million fittings sold, plumbers and pipefitters across the U.S. agree that Viega was starting something great back in 2012.

Superior engineering

Viega MegaPress pipe fittings were the first press system in the U.S. market specifically engineered for gas and hydronic applications. Since its introduction a decade ago, Viega MegaPress systems have expanded to include more than 200 configurations from ½” to 2” and are approved for more applications than any other carbon steel press fitting system.

The value of MegaPress fittings can be found in their unique engineering. The separator ring keeps the sealing element outside the flow path to increase system lifespan and stand up to a broad range of pressures, temperatures and applications. All Viega fittings come equipped with Smart Connect® technology that identifies unpressed connections during pressure testing. It’s a little feature that lets you know Viega fittings are installed right the first time.

A market hungry for more

While the introduction of MegaPress was a game-changing moment in plumbing history, contractor demand for more applications grew instantly. And our research and product development teams worked around the clock to expand this safer, time-saving pipe connection method into areas no other fitting manufacturer had gone.

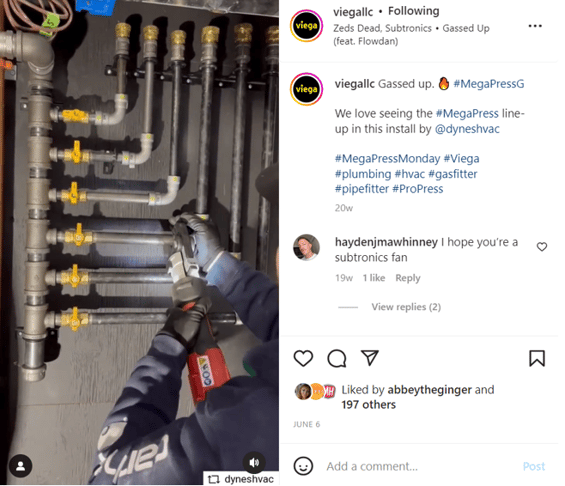

We introduced MegaPressG with an HNBR sealing element approved for use in gas and fuel oil applications. Initially available ½” – 2”, MegaPressG also became the first fitting approved for connecting gas pipe up to 4”.

See MegaPressG in action:

MegaPress FKM includes an FKM sealing element that allows for installation in higher-temperature applications. With more than 180 configurations ½” to 4”, MegaPress FKM is now a staple in residential and low-pressure steam, compressed air, fire protection and fuel/oil applications.

Learn more about MegaPress FKM:

We also designed a system for connecting large diameter 304 and 316 IPS stainless steel pipe. MegaPress Stainless comes with a choice of EPDM or FKM sealing elements and makes secure connections in less than 16 seconds.

See approved applications:

The complete system

As the adoption of press fitting systems grew, we expanded our systems further to meet contractor demand with our complementary valve offering. This included Viega MegaPressG Valves which come with HNBR sealing elements and are available in sizes ½” to 2”. And Viega MegaPress 3-piece ball valves which are available ½” all the way up to 4” and work on potable water, hydronic water and a wide range of other system applications.

Constant innovation

As we celebrate 10 years of MegaPress pipe fittings and valves and more than 22 million units sold in the U.S., our commitment to innovation continues. Here are a few significant milestones.

To stay current on the latest product releases, make sure you’re signed up for Viega emails.

Revolutionize your pipe connection methods

MegaPress systems are proven to work and guaranteed to last. Browse the complete line and see how you can start saving your facility up to 90% in installation costs with Viega pipe fittings.

*Applications for all metals including MegaPress®