How can I prep pipe for press fittings?

Preparation is key to getting a secure press when joining pipes. It provides two primary benefits:

• It helps ensure a good fit with the sealing element in the fitting

• It allows you to judge the quality of the pipe you’re working with

Inspect the Pipe

It begins with inspecting the pipe. Nowadays, pipes could be domestic or produced overseas. If you’re picking it up from a distributor, inspect it as best you can. We’ve seen pipes with cracks along the weld seam and track marks from extruders, both of which can cause failure.

Of course, as a contractor, you don’t always get to pick the pipe you use but spotting problems beforehand can eliminate big problems down the road.

Remove the Coating

In many cases, you’re going to use a pipe that’s rusty, painted or lacquered or that comes pre-coated from the manufacturer. The covering needs to be removed or, at least, thinned. In some cases, manufacturer pre-coating is so thick that you have to partially remove it to get a good fit.

Four Easy Steps for Pipe Prep:

1. Measure your pipe and make the cut.

2. Ream and deburr the inside and outside of the pipe. Band saws and dry cut metal saws, which you’re likely to use in the field, are fast and effective, but their cuts do need to be deburred.

3. Mark the fitting insertion depth on the pipe using an insertion depth gauge, tape measure or dry-fit a fitting, making sure that the pipe is bottomed out in the fitting.

4. Clean the pipe from its end to the insertion mark, using sandcloth or scouring pads. Clean it enough to smooth the pipe and remove lacquer, paint, rust, irregularities, etc. While you don’t have to get down to the bare metal, you should remove enough of the covering to be able to inspect the quality of the pipe and make sure it’s sufficient for pressing. You want a smooth, clean surface for the sealing element to seal upon.

If you’re doing a large number of fittings on a job, using a flap wheel grinder on a cordless drill to clean the pipe will save time. Note: We don’t recommend using an abrasive flapper wheel or 80-120 grit flap sanding wheel on the galvanized pipe because it can generate toxic dust particles, but if you do, wear a mask.

Pipe preparation takes only a few seconds but goes a long way towards ensuring a quality press.

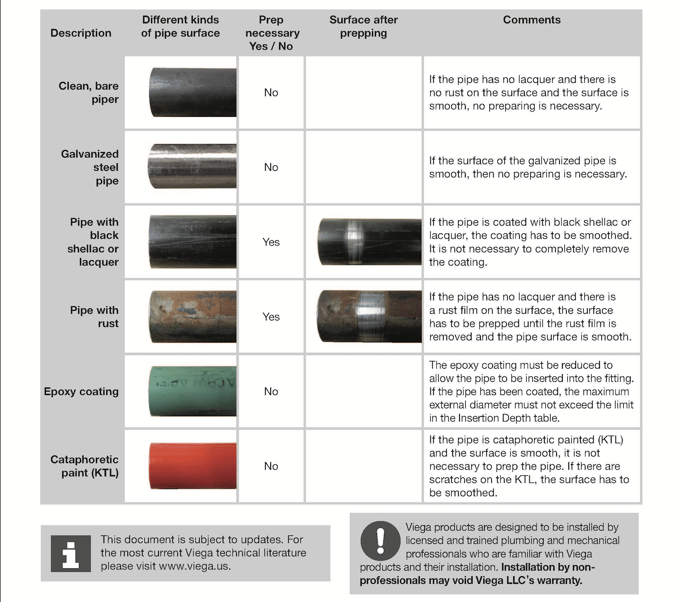

For reference, check out Viega's guide on pipe preparation. It lists out the different kinds of pipe surfaces and gives recommendations on how the pipe should look before pressing on a MegaPress fitting.