Pressing fittings is fast, safe and secure, but that doesn’t mean it’s as simple as pulling a trigger on a tool. As with most plumbing work, preparation is key to success. Prepping pipe for is simple, but important.

Pipe Inspection

As a contractor, you don’t always get to choose the pipe you work with, but you’re still responsible for checking its condition before installation. Whether you’re picking up at a distributor or seeing it for the first time at a jobsite, give it a once-over. Look for corrosion, cracks along the weld seam and track marks from extruders.

Pipe surfaces must be smooth, free of indentations, pits and deformations. They should be clean and free of debris, rust, scale, paint, oil and grease. And avoid pressing over grooves, manufacturers stamps, or engravings on the pipe surface.

Cutting Pipe

A good seal starts with a good cut. Measure carefully and cut straight. A displacement cutter, bandsaw, reciprocating saw, chop saw, roll cutter or any fine-toothed saw will work.

Then ream the inside of the pipe and deburr the outside. A smooth inside ensures good flow and a smooth outside eliminates any sharp edges or lips that could interfere with the press.

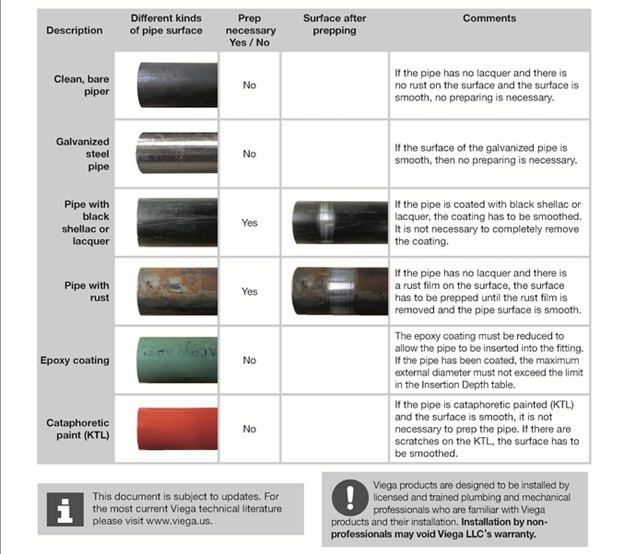

How to Remove the Coating

Copper and smoother-surfaced alloys such as stainless steel and CuNi tubing/pipe don’t require surface prep. As a rule, neither do new installations of piping assemblies and equipment. That’s why most pipe prep comes during maintenance and repair.

Mark the fitting insertion depth on the pipe using an insertion depth gauge, tape measure or dry-fit a fitting, making sure that the pipe is bottomed out in the fitting.

Prep the pipe from its end to the insertion mark. You can use traditional plumbers’ sandcloth, a scouring pad, an 80-120 grit flapper wheel with a drill, or a drill equipped with a RIDGID MegaPress prep tool with abrasive strip. Do not use a flap disk because it can leave flat spots or bellies on the surface of the pipe leading to an improper sealing surface.

It is not necessary to completely remove protective coatings or to expose the bare steel material.

If the pipe is coated with black shellac or lacquer the coating must be smoothed; follow our pipe prep chart below or in the MegaPress installation manual. “Freckling,” when you see bare steel show start to show through the black coating, is an indicator the surface is smooth and prepped properly.

Pipe preparation takes only a few seconds but goes a long way towards ensuring a quality press.

For reference, check out Viega's guide on pipe preparation. It lists the different kinds of pipe surfaces and gives recommendations on how the pipe should look before pressing on a MegaPress fitting.

For more on pipe prep, check out these Tech Tip Tuesday’s: