Slip couplings, which are also known as repair couplings or no-stop couplings, are helpful products for making repairs in tight spaces.

Unlike regular couplings, slip couplings lack the internal ridge or dimple that limits how far a pipe can be inserted into them, so they can slip right over a pipe or tube, which is how they got their name. Slip couplings come in regular and extended lengths for different project needs and situations.

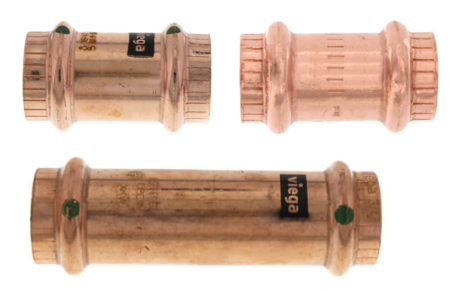

Coupling, Slip Coupling and Extended Slip Coupling

Top Row: Slip Coupling (no-stop), Coupling (stop)

Bottom Row: Fitting Extended Slip (no-stop)

*Images not actual size

Most commonly, Slip Couplings are used to replace a section of pipe or tubing that must be cut out due to a leak or corrosion. Their length allows repairs to be made in tight spaces and when the tubing being repaired can’t be easily moved.

While slip couplings lack internal stops, they do have minimum and maximum allowable insertion depths. When using them it’s important to mark the insertion depths to ensure a secure fitting.

Here’s a demonstration with MegaPress:

And here’s one with ProPress copper:

Viega offers regular and extended slip couplings in ProPress copper and stainless, MegaPress for black steel, SeaPress and MegaPress CuNi for marine use.