In Camden, New Jersey, there’s a piece of history that everyone should have an opportunity to see. The USS New Jersey – nicknamed Black Dragon – is the largest of four Iowa-class battleships that served the U.S. Navy during and after World War II. This impressive vessel is 887 feet, 7 inches long and served in all of America’s major conflicts from 1943 until 1990.

Commissioned into service on the first anniversary of Pearl Harbor in 1943, she saw more combat than any other battleship in history. The USS New Jersey fought in World War II, the Korean War, Vietnam (the only battleship to serve in this conflict), the Cold War, and the Persian Gulf, among others. The USS New Jersey was decommissioned in 1991 but remained on the reserve fleet until 2000. In 2006, President George W. Bush signed legislation permitting the USS New Jersey to become a museum. The other surviving Iowa-class battleships – The USS Iowa, Missouri, and Wisconsin – all serve as museums.

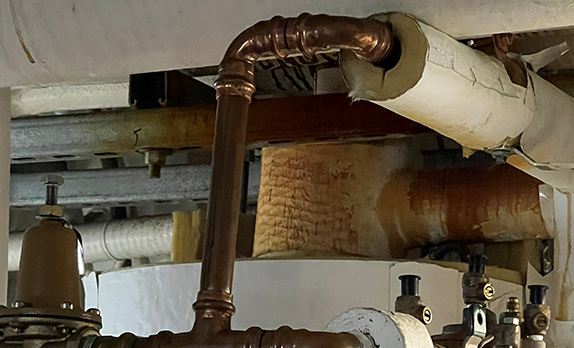

Now permanently docked in Camden, New Jersey, the reality of a ship built in the 1940s is that it needs daily repairs and maintenance. Local plumber Vincent Tinervia of Tinervia Plumbing, learned that Battleship New Jersey needed a new water meter installed and some plumbing re-piped while chatting with a docent on a tour of the museum with his daughter. Tinervia reached out to Viega about donating the fittings for the installation.

Working on the ship, Tinervia was amazed by the size and scale. “The ship is massive,” he said. “Everything is super-sized. And because of the ship’s age, you never know what sort of can of worms you’re opening when you attempt a repair because nothing is a standard size.” He said it is an honor to volunteer his time for the work on the USS New Jersey. “How many times can you say you’ve worked on a battleship?” he said.

For this project, Tinervia is installing water meters on the ship and on the accompanying land building so the water company can charge for the water provided to the ship. Tinervia will re-pipe the lines to fit the water meters and add a 3" ProPress Ball Valve for the water to come off the ship. He has been using Viega for more than 15 years and is using 3" ProPress copper fittings and a RIDGID 340 press tool with ProPress jaws for the installation. “Viega really made the most sense for this project,” Tinervia said. “I don’t have to worry about a hot work permit or fire.”

Ken Kersch, Director of Camps, is also a former crewmember of the USS New Jersey. He has been sharing his story as a tour guide and directing camps for the past 21 years. He works with scouting groups and families who have an opportunity to spend a night on the ship. They experience what it was like to work on the ship, sleep in the bunks, prepare meals in the galleys, and see the machine shops, carpentry shops, and other systems that kept the ship running.

Kersch said that these battleships would typically have a crew of 1,600 doing daily maintenance of the deck, plumbing, paint, and other systems on the ship. Today, the USS New Jersey has a crew of 14 and other volunteers who work to maintain the ship daily. They are replacing teak decking that has worn away and other repair projects to keep the ship open for visitors. “I hope that visitors to the USS New Jersey come away with an appreciation of the history of the battleship and what it meant for the thousands of soldiers who would spend 30-60 days at a time out at sea, away from their families, to serve and defend the United States.” Learn more about Battleship New Jersey and how you can visit at https://www.battleshipnewjersey.org/.

From cruise ships to battleships and from commercial to offshore operations, Viega knows that marine vessels experience unique obstacles and working conditions. Through rigorous testing, Viega systems have earned a litany of marine certifications from governing bodies across the U.S. and abroad. Learn more about our marine solutions at https://www.viega.us/en/homepage/guided-solution/marine-solutions.html.