For those who’ve never done it for a living, plumbing might seem like it doesn’t take a lot of thought: stop leaks, fix pipes, install hot water heaters, etc.

But those who have done it know better: Most plumbing jobs require a lot of thought and skill before the first wrench gets turned. At every level but the simplest, plumbing can require:

- Diagnosing the problem(s)

- Devising the solution

- Choosing the right materials

- Choosing the right equipment

- Managing the workspace

- Working safely

- Doing the work correctly

- Testing the work

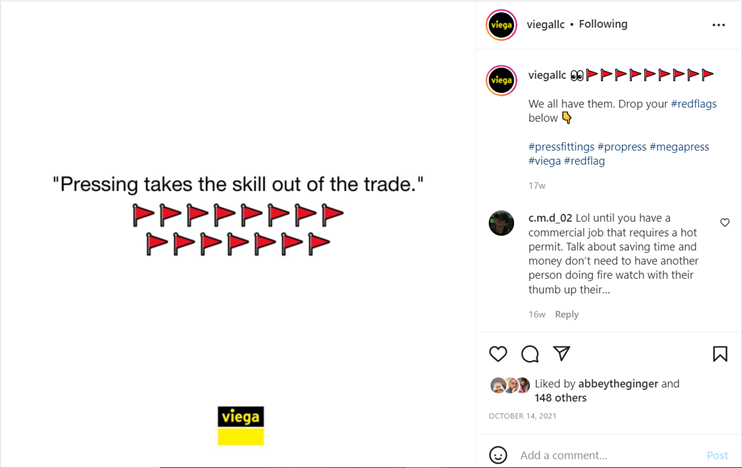

Yet, even with all that, there are those who argue that using press-technology instead of soldering or threading, somehow takes the skill out of the trade. To reduce plumbing skill to the method of joining pipe is to ignore everything else that goes into it. While press fitting technology makes it simpler to join piping/tubing assemblies, it doesn’t tell the contractor what materials to use or where to install them. The skill is knowing why we as plumbers do the things we do, practicing and upholding a standards of excellence, to ensure the proper installation of plumbing systems to protect health and promote safety.

"So, for years I was a “solder”-only plumber and swore I’d never use a ProPress. But one day I went to help a buddy of mine, who’s a very successful plumber and business owner, rough in a master bathroom. He broke out his ProPress and the very awesome @viegallc ProPress fittings(😉). Not only did we finish 2 hours faster, but I was SOLD on propressing. Bought a decent used press tool after that and haven’t looked back. Sure, it’s different but if all your “skill” is soldering, you should probably re-evaluate your skill set. Just my opinion. Thank you for giving us the tools we need to evolve as tradespeople and plumbers 👏🔥👏🔥"

The Evolution of Plumbing

Plumbing, like every other trade, has evolved over the years to incorporate better tools, materials, and techniques. The profession has come a long way since the Egyptians first used copper pipes in 2500 B.C. And every advancement was good for not only plumbing, but for the civilization that depended on it as well.

When something better comes along, the trade adopts it while retaining the older techniques and materials that are still important. Other things get left behind (made any lead joints lately, for an entire piping system?).

Press technology vs traditional methods of joining pipe isn’t an either-or situation. Taking up pressing doesn’t require swearing off the other methods. Every method has its uses. That’s why Viega technical consultants at our seminar centers in Colorado and New Hampshire teach soldering and threading in addition to pressing. Those are skills that will always be needed. The smart contractor uses the best method for the job.

"Very hesitant in the beginning, not going to lie. Not sure it was safe, reliable, or lasting but knock on wood been using Viega ProPress fittings about 15 years now with no issue and we love it. Much more efficient especially when it comes to larger fittings 2"- 4". Back in the day it was cut and groove for pipe 2-1/2" and up or solder. Do you know how long it takes to solder a 4-inch fitting? A LONNNG TIME!!! I personally appreciate the constant evolution! 👍💪"

"I was the last guy in the company to start pressing boss had to force it on me! Now I'm the biggest proponent for press! #viegaonly when it comes to our #pressfittings"

Pressing Helps Business

While plumbing is a trade, it is, above all, a business. A competitive, demanding business in which saving time is crucial.

Contractors who resist press fitting technology for the sake of “saving the trade” and who spend unnecessary hours soldering or threading put themselves at a competitive disadvantage against those who can do the job faster and more efficiently through pressing.

Pressing saves hours on smaller jobs and days on big commercial and industrial projects. That reduces labor costs and frees up time to take on additional jobs. What were once two-person jobs now require only one person. That means small shops can take on jobs that were once out of reach.

And because pressing is flame-free, it’s better suited for work in close quarters, like attics, or in settings like hospital rooms and industrial plants, where the presence of volatile gases makes it too dangerous to do hot work.

It’s true that press tools and fittings aren’t cheap, but the initial investment pays off quickly in time saved, labor costs and additional jobs.

For 20 years, press technology has been winning converts in this country. It’s made the job efficient, safer, and more profitable for those who use it. And none of those contractors have lost an ounce of skill.

Don’t Just Take it From us...

"I purchased the system because my son was working with me and after years of welding and soldering, I didn’t want that in his lungs so I bought into ProPress and never looked back,"

"I held out on getting this... Then I had a big job where I knew I'd need them.... After the first few presses with them I realized just how much time I was wasting planning out my repair/make-ups so I could press everything b4 I got this set. That for me is far more valuable that just getting one tight space press done, I can rail through a job without having to spend a lot of time planning every single press.... Basically, I was doing yoga with my RP when I should have been sitting in the pool 😂"