While PEX-a, PEX-b or PEX-c is commonly misconstrued as a quality rating system, the variations actually refer to how PEX is cross-linked. PEX-a uses peroxide, PEX-b uses silane and PEX-c uses e-beam.

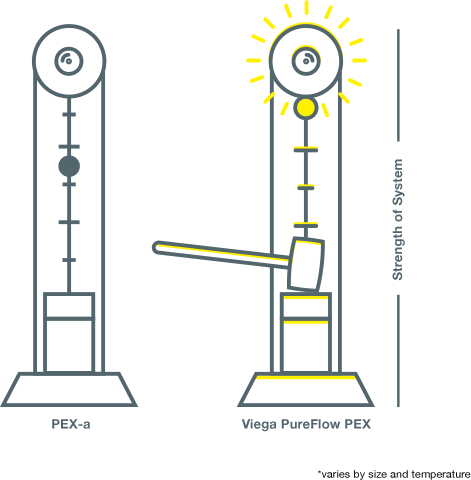

In terms of chlorine and UV resistance, PEX-b offers the most protection, according to industry standards. While high chlorine resistance is important for hotwater recirculation systems, high UV resistance delivers peace of mind for construction applications with long schedules or with the likelihood for delays. PEX-b also has higher burst pressures compared to PEX-a, which translates into less potential for operational failures.

These differentiators are reflected in the four-digit material designation code printed on PEX tubing as a quality standard. For guidance on how to make an informed decision, consult this overview of PEX designation standards.

When it comes to the performance of water distribution systems, reducing water waste and hot water delivery times are top priorities. The choice of how to install a PEX plumbing system will either support or deter these efforts.

With this in mind, there are three installation methods industry leaders recommend: branch and tee, combination and home-run systems. The most conventional of the three, branch and tee, is best suited for condensed floor plans, while the more streamlined combination method is ideal for areas with multiple fixtures grouped together.

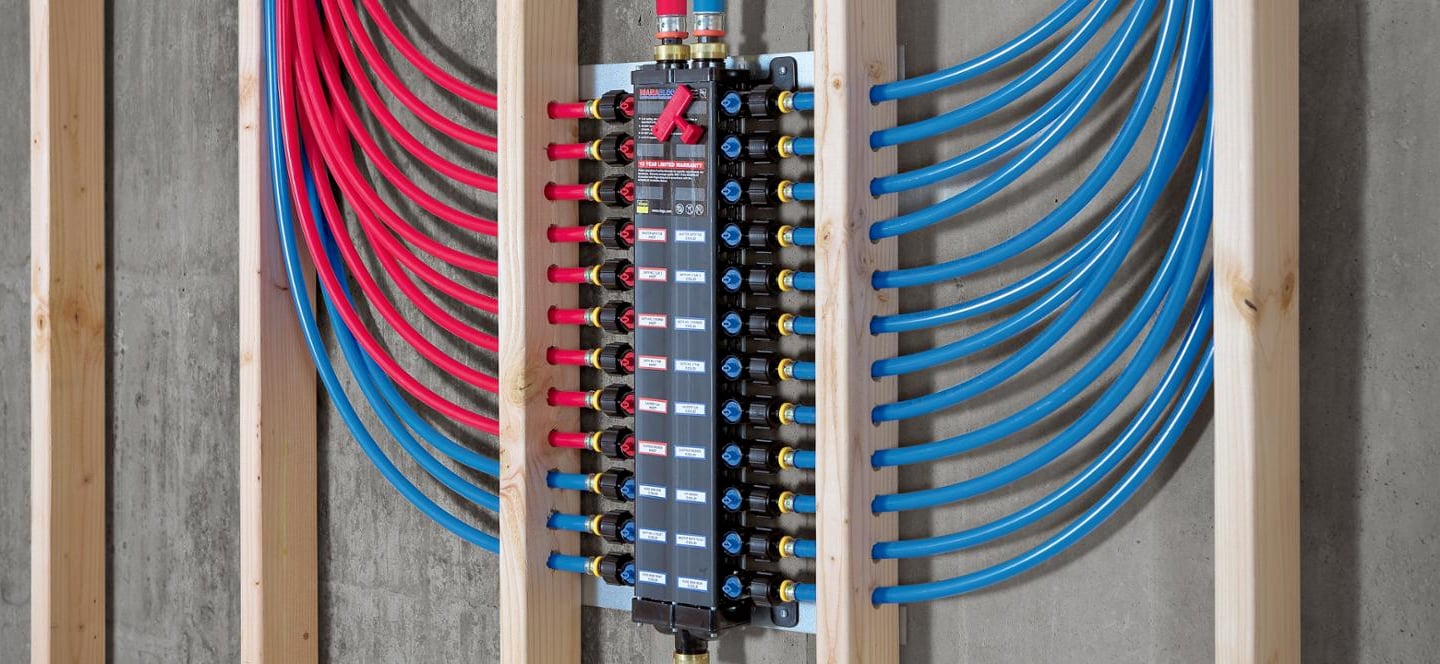

In cases where space allows, home-run systems are the optimal choice from an operational efficiency standpoint. With individual distribution lines to each fixture in a system, this installation method can decrease water waste by as much as 40 percent compared to traditional systems and deliver hot water up to four times faster than other configurations. Not to mention, they also require fewer connections behind the wall.

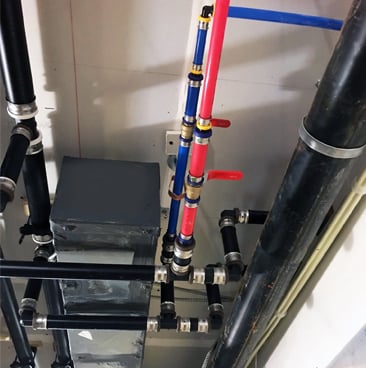

At Ryco Inc., Uponor was once the manufacturer of choice for pipe fittings. But roadblocks like heavy, cumbersome tools and slow installation times prompted the conversation about a switchover.

“Commercially, we do a lot of 2" or 1¼" risers in hotels and multi-unit jobs, and the Uponor tool must weigh something like 50 pounds,” said Jeremy Richter, who runs the company’s residential division. “It’s so big and heavy, and being up on the ladder with this thing is terrible.”

Recognizing the time wasted, Richter decided to try Viega PureFlow as an alternative. The first place these products were put to work was at the Mt. Lebanon senior apartments in Mt. Lebanon, Penn.

Not only did the team experience no issues during the installation, but it saw significant time savings. “We estimate — and we’re big on historical data — that we’ve got at least a 25 percent savings with PureFlow Press on the Mt. Lebanon job," Richter said.